Extreme Weather Reveals True Strength of a Home’s Metal Durable Roofing System

Strong winds can put the structural integrity and quality of building materials to the test, and a home’s roofing system endures the most punishing force of these gusts. ProVia metal roofs are engineered to withstand heavy winds and minimize damage.

Any new roof can look nice on the surface, but the true strength of a durable roofing system is revealed when extreme weather conditions prevail. Raging wind and driving rain. Relentless heat and stifling humidity. Heavy snow and bitter cold. These extreme weather conditions can put the structural integrity and quality of building materials to the test, and a home’s roofing system endures the most punishing force of these formidable weather events.

In the case of heavy winds, roofing is highly susceptible to abuse and destruction. Strong gusts can damage shingles over time by loosening or weakening the attachment areas, creating stress points and compromising the integrity of the installation. Wind can work its way beneath a loose shingle and lift it, creating an opening that will sustain further damage with repeated exposure. Windborne debris can puncture shingles and loosen them from their point of attachment. The perimeter and corners of a roof are particularly vulnerable, as they are exposed to the full force of extreme winds.

Weathering wind, resisting rain—metal roofs are built to withstand

Most metal roofs are engineered to withstand high winds and endure impact from hail or flying debris. Moderate winds between 86-110 mph can damage an asphalt roof, but a typical metal roof system can withstand wind speeds of 140 mph. Metal roofs have shown success at minimizing damage in hurricane-prone areas and are impervious to heavy downpours and water penetration that accompany these severe storms as well.

Florida building code requirements for certification of residential metal roofing in High Velocity Hurricane Zones and non-HVHZ areas include: TAS 100 wind and wind-driven rain resistance; TAS 110 salt spray and Xenon arc weathering; and TAS 125 uplift resistance for roofing panels and fasteners. Contractors should look for metal roof systems that are tested and witnessed by a third-party laboratory and evaluated by an accredited entity.

More than just a panel—superior installation techniques yield unrivaled performance

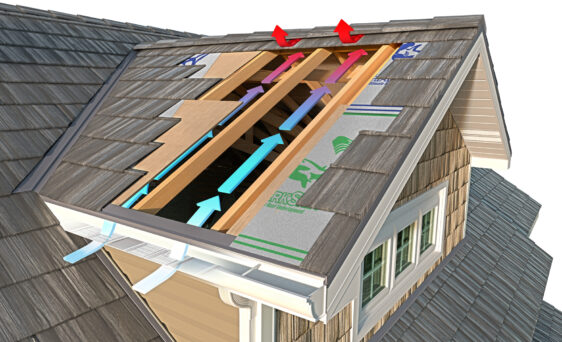

Metal roofing systems with interlocking panels and fasteners that attach at multiple points provide superior performance and weatherability. Interlocking panels connect to create a strong bond and reduce wind intrusion, and multiple fastener points provide secure edge-to-edge attachment to the structure. Proper, professional installation is key to performance – FEMA advises contractors to specify a metal roofing system that is tested and certified to withstand high windspeeds; calculate load provisions in accordance with building code ASCE 7; and ensure that underlayment and fastener components are suitable for the application.

Case study—withstanding a derecho in Kansas

On Wednesday, December 5, 2021, a record-breaking wind event wreaked havoc across the Great Plains region. A serial derecho produced severe thunderstorms, damaging winds, blowing dust and even grass fires. A derecho causes destruction as an inland hurricane might do—the winds blow strongly in a straight line, and the damage is spread over a long, wide area.

The straight-line winds blew strongly in the region from 2:00 until about 6:00 p.m., with winds gusting from 55 to 85 mph. Buildings in the area sustained damage from the heavy gusts: a prefab metal shell used for storage was ripped from its moors and propelled down the road by near-hurricane-force winds. Wide-spread power outages were reported in the area—75 power line poles had snapped.

In Hutchinson, Kansas, the wild winter windstorm kicked up ominous dust clouds and launched debris through the air. Local contractors Pleasantview Home Improvement had called their crews in due to the dangerous conditions, but office staff kept a watchful eye on the storm as they continued working. The company had installed a ProVia metal roof system on the front of the building in 2019; the stamped metal panel roof endured four hours of sustained, straight-line winds and abuse from the dust storms, with no damage—structural or cosmetic. Unlike many other structures in the area, the ProVia metal durable roofing on their facility held fast amidst hours of shear and straight-line winds.

Strong roofing system technology

The engineering that went into making ProVia metal shake roofs superior performers in weather resistance also resulted in a product that is better for the environment than asphalt shingles. Learn more about our metal house roofing technology and the benefits of metal roofing.

Last Updated: September 27, 2022

Stay up to date with our latest blog articles